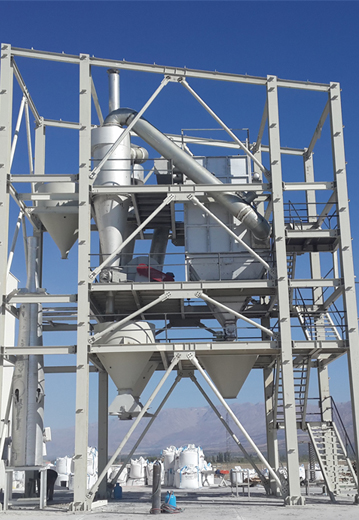

Perlite Expantion Plant

Perlite facilities designed by IPS are designed according to the land, fuel, capacity and the quality of the product to be produced.

After the perlite crushing and sieving coming from the kiln, the moisture content is made suitable by drying. The expansion furnace used in the system consists of 2 parts and is made of 310 S material resistant to high temperature. Rocket feeding is adjusted by frequency converter and raw perlite is fed from 4 points to the kiln center. The burner is used in the system depending on the type of fuel with the calorific value calculated by our company according to the capacity value.

Feeding and set values according to the temperature relative to the produced heat value can be controlled from the burner panel in automation or in the field. The produced product can be bagged depending on demand or it can be shipped to another unit downstream of the line.

The system works under full automation. The operator can manage the facility from the screen. Temperature values in the system, operating positions of the machines, rocket feeding amount can be seen by the operator on the screen.

Download PDF Datasheet

Please download IPS Makina general catalogue from the link below.

Download PDF