Gypsum Plasterboard Production.

Plasterboard, called as by different brand and names, gypsum board / plasterboard / wallboard, is described as flat rectangular boards made from gypsum core which is pressed into two layers of cardboard according to EN520+A1 standards.

Area of use

Gypsum board is material with high activity and low cost used as sheeting of interior surfaces of commercial or residential buildings. Structure of gypsum boards provides fire resistant, sound and heat insulation where required.

Gypsum are fixed on to the surface by means of nails, screws and gypsum-based adhesives and other various types of adhesives. Depending on area of use, gypsum boards are selected as per their type, form, thickness and edge shape, and are used as dry surface sheeting, suspended ceiling covering, wall partitioning elements or curtain covering on supporting beam or columns.

Gypsum plasterboard production process

In order to produce gypsum plasterboard, first, you need gypsum powder production process.

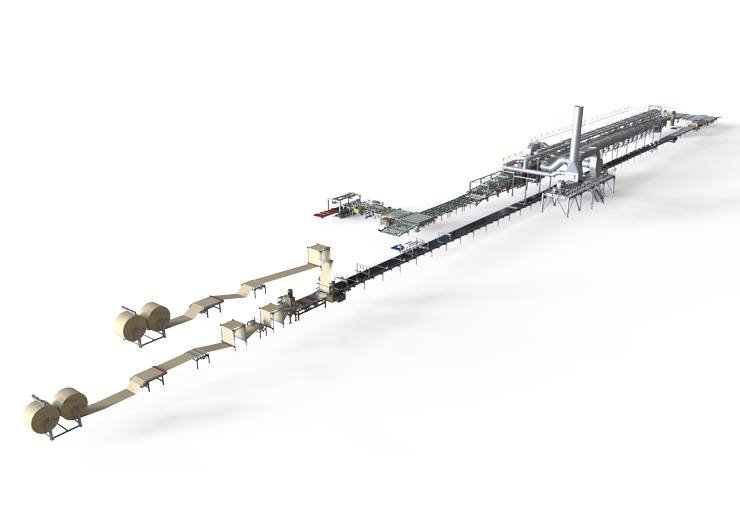

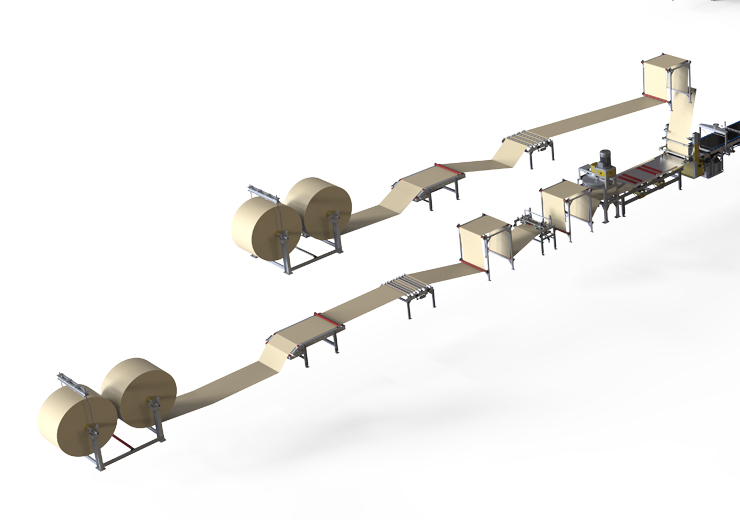

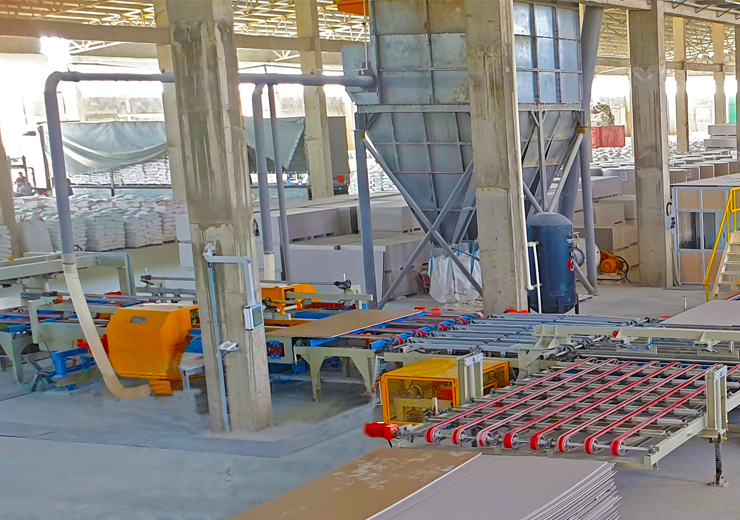

Gypsum powder, produced with a calcination process under suitable conditions in gypsum production process, stored in silos for further use in gypsum plasterboards production. Gypsum powder, water and wet & dry additives are fed to high-speed mixer where homogenous mixture is prepared, and then the mixture is poured into two layers of cardboard prepared in the production line. Cardboard edges and sides are bended and required thickness is obtained in forming unit, and continues on long belt conveyor for setting. Gypsum board after obtaining required setting is cut in length by the cutting knife and then transferred to dryer unit. Dried gypsum boards are trimmed in bundler unit and then packed for further dispatch to customers.

Types of plasterboards

Gypsum boards, as briefed above, are differ from each other in production technology according to are of use, thickness and length as described inEN520+A1 standards. In the before mentioned standard (EN520+A1) gypsum board types are described as Type A, H, F, E, P, I, R and D, and dual or trio versions (e.g. Type HF, IR etc.)..

In the same way, thickness of gypsum boards varies from 6mm to 18mm.

Edges of gypsum boards may have different shapes, such as tapered edge or square edge.

Most preferred gypsum boards types as shown above are Type A, H and F.

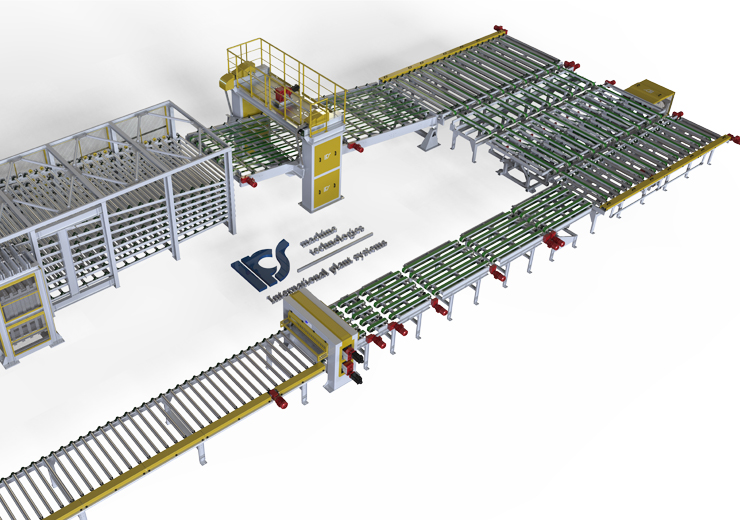

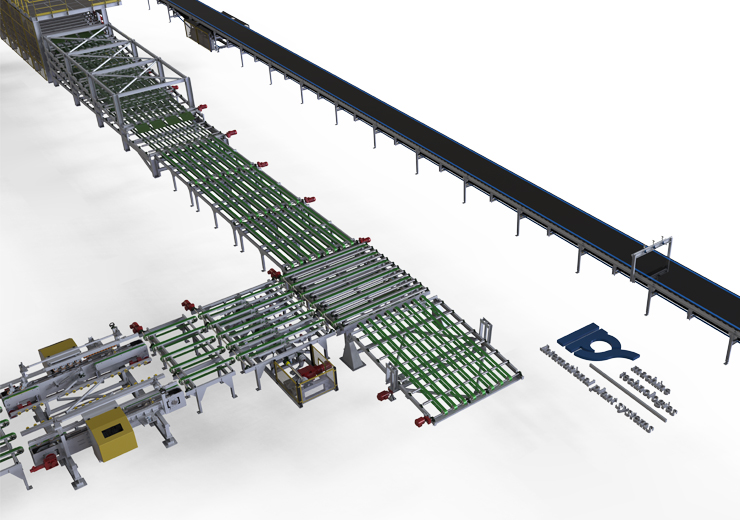

Plasterboard production line equipment and units

- Dry materials preparing station

- Wet materials preparing station

- Cardboard Handling and Preparation Unit

- Stucco mixer

- Vabrating table and form-press unit

- Setting belt conveyor

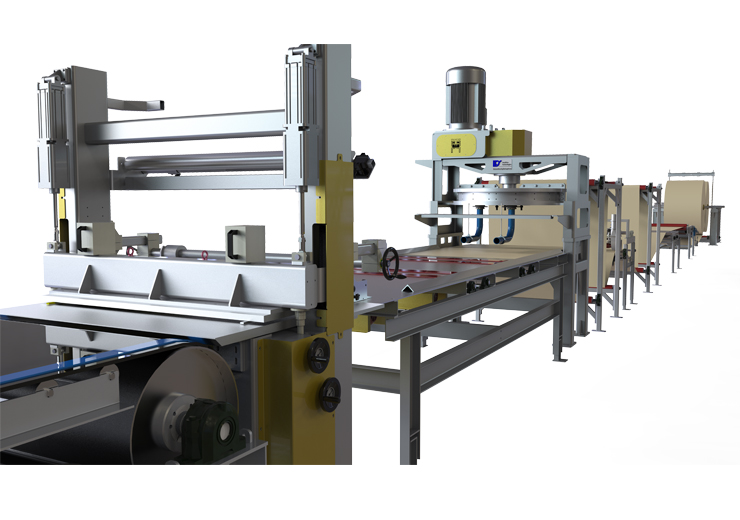

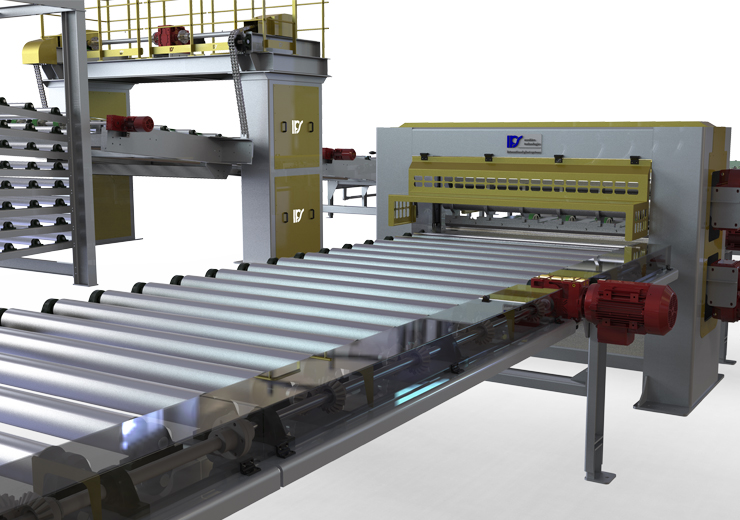

- Knife - board cutting machine

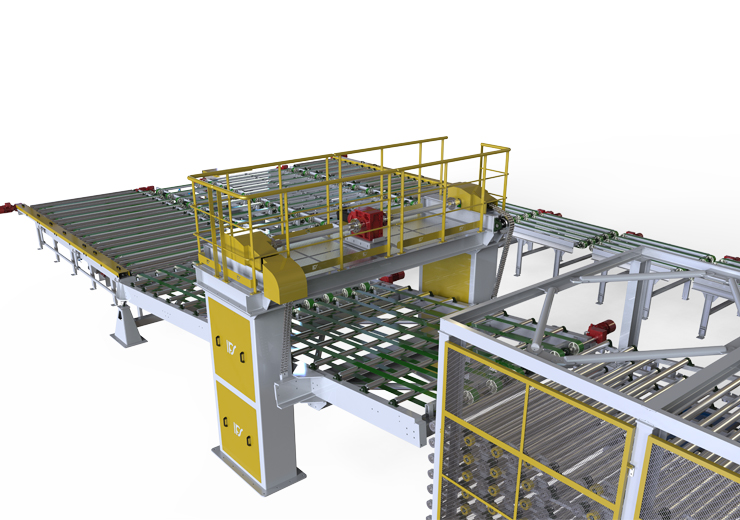

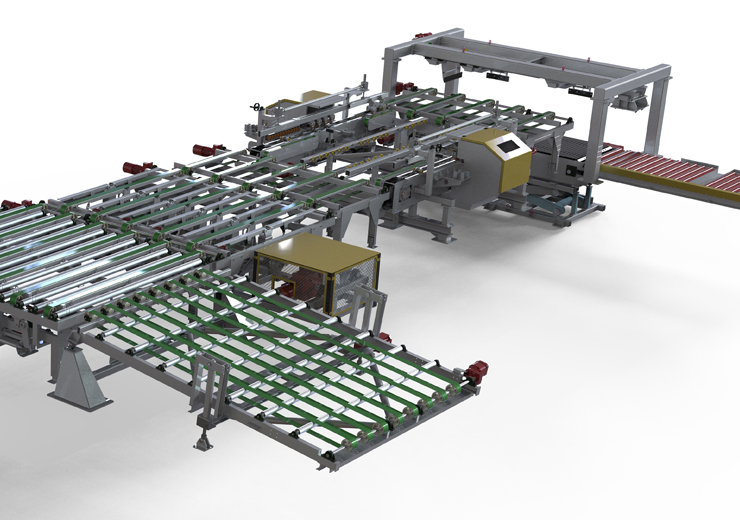

- Cross-conveying units

- Dryer inlet group

- Dryer

- Dryer outlet group

- Heat Exchanger

- Bundler - board trimming machine

- Stacking unit

Technology | Gypsum plasterboard production technolgoy is developed and improved with state of the art technology and with IPS Makina's long experince in the industry.

Knowledge | Gypsum plasterboard production formula is developed and improved with the knowledge that assures optimal production cost and quality ratio..

Download PDF Datasheet

Please download IPS Makina general catalogue from the link below.

Download PDF