Stacking table

– final handling of the boards

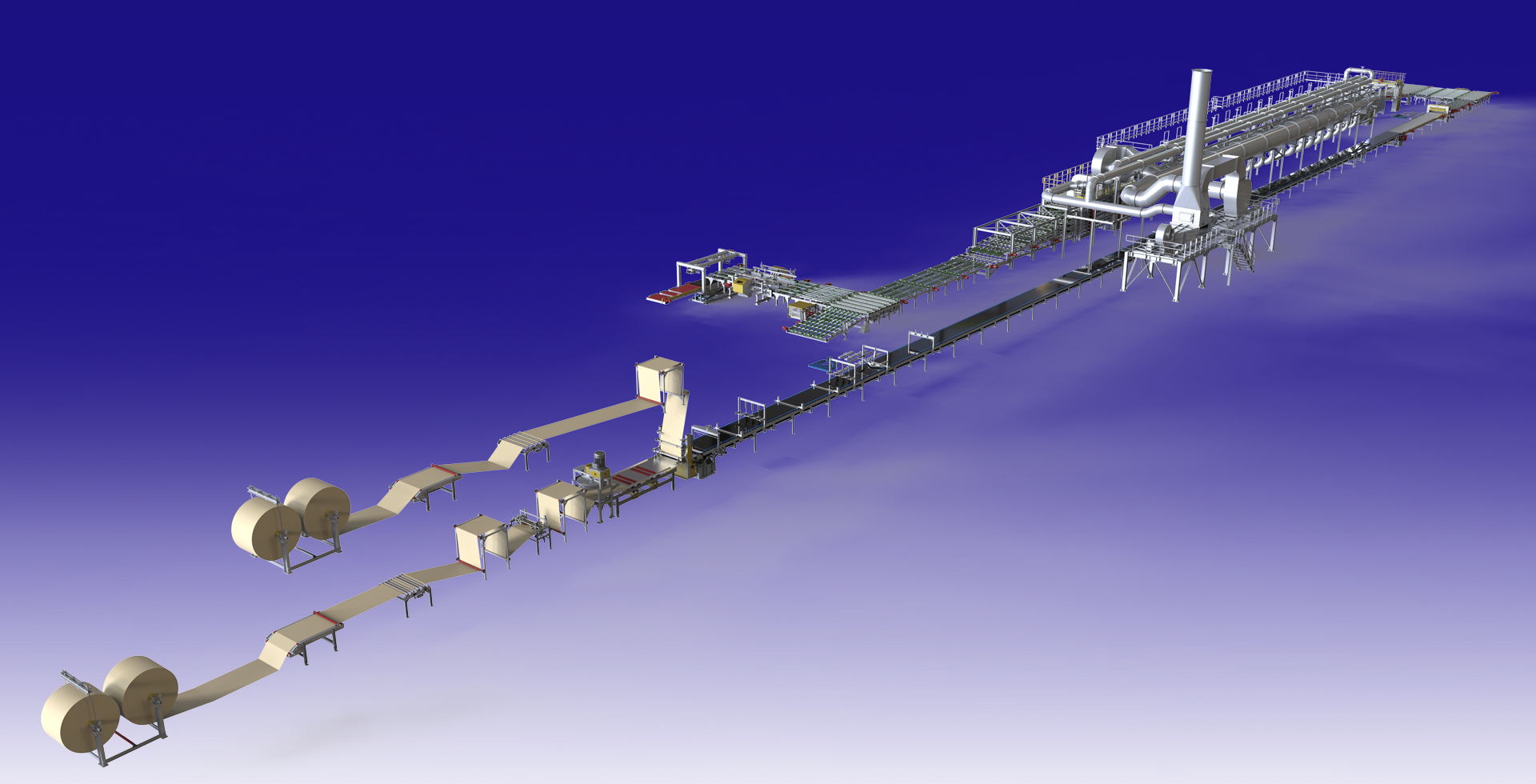

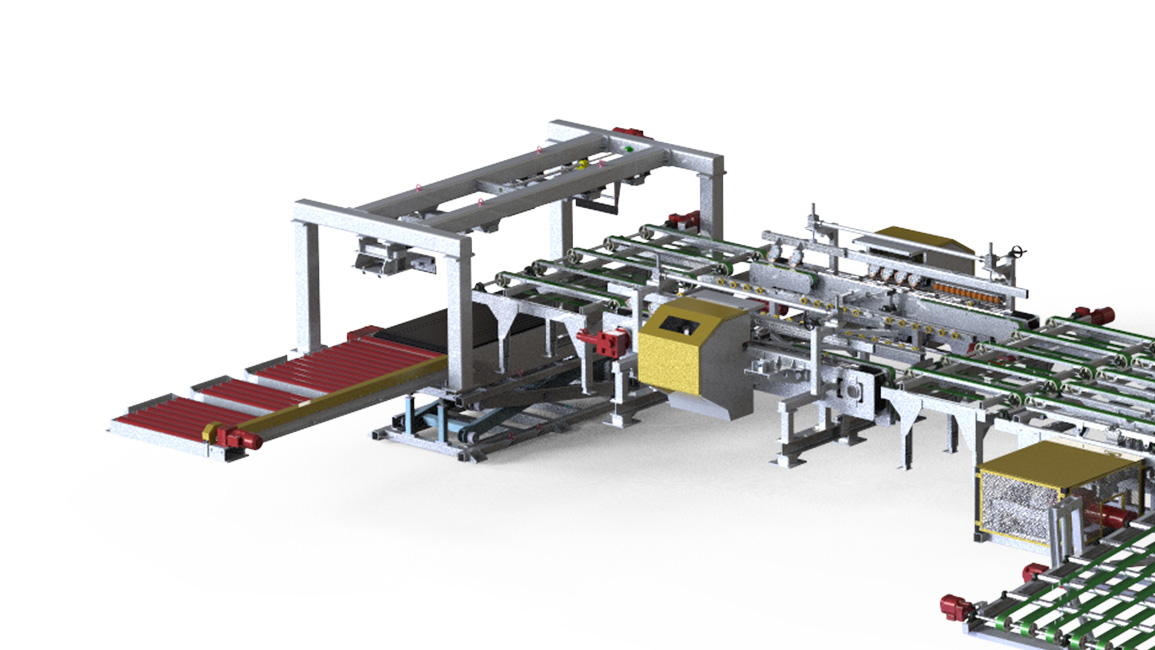

The Stacking System is the final stage of the plasterboard production line, where finished boards are systematically stacked for storage, packaging, and for further shipment to the customer. Designed for smooth handling and accurate alignment, this system ensures that boards are prepared for forklift pickup and further logistics with maximum care and efficiency.

The stacking system includes:

- Stacking Preparation Table – receives boards from the bundler and prepares them for stacking sequence

- Stacking Feeding Table – transfers boards in a controlled flow toward the stacking area

- Stacking Aligning Unit – ensures boards are properly aligned for uniform stacking, preventing misalignment and edge damage

- Forklift Take-Off Table – holds the completed stacks, making it easy for forklifts to pick up and move the product safely

Together, these units provide a reliable, automated stacking solution, minimizing manual handling, reducing product damage, and ensuring the boards are market-ready