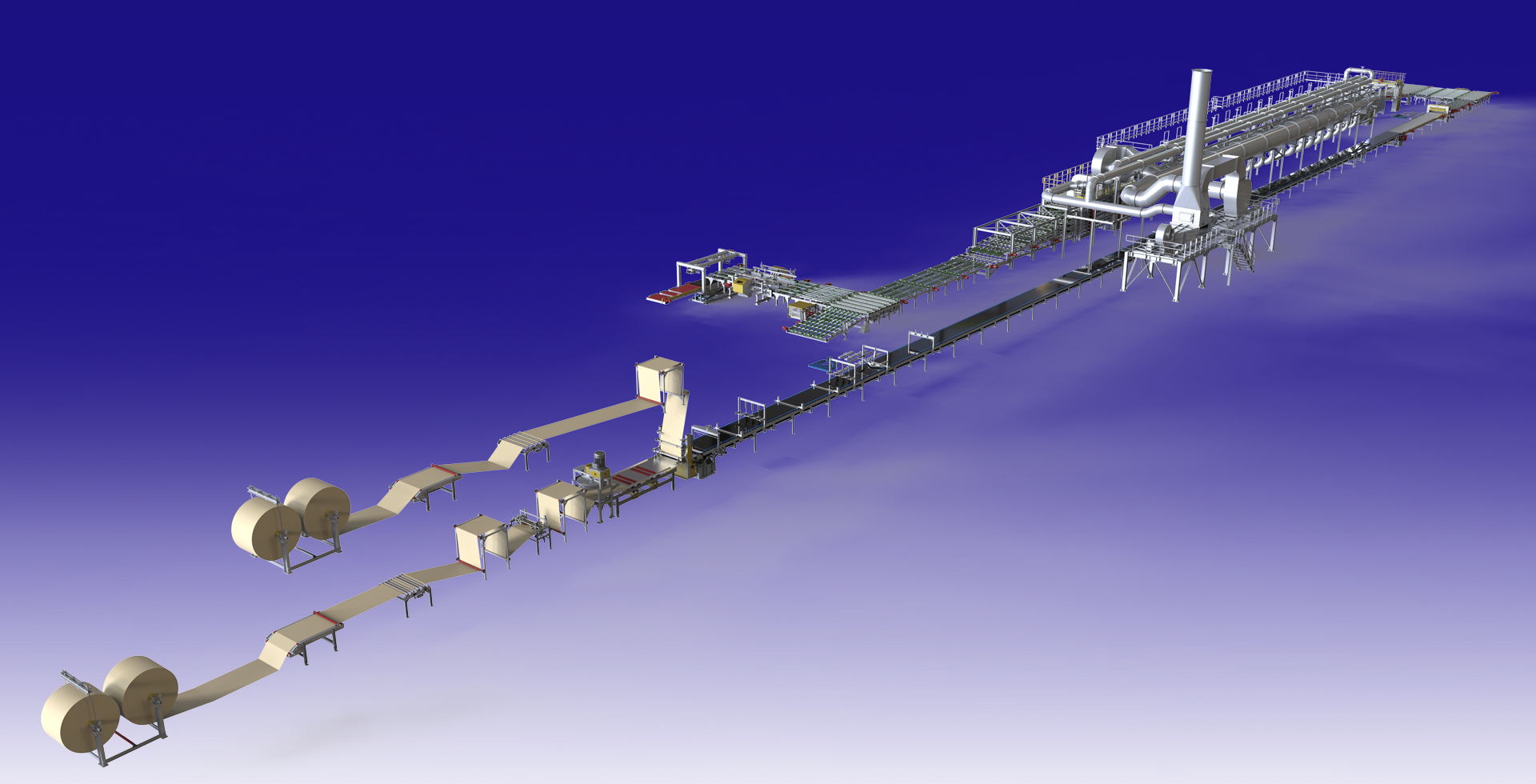

Bundler

– Precision Trimming and Finishing for Plasterboard Edges

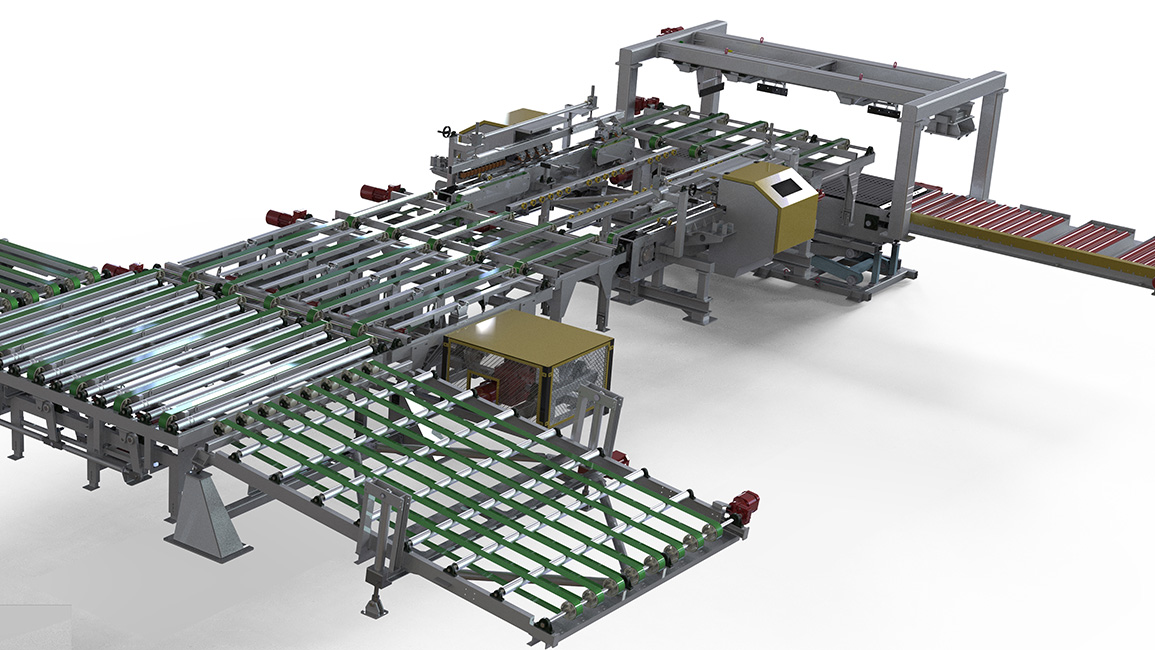

The Bundler is a precision-engineered machine in the plasterboard production line, designed to perform final edge trimming and optional edge banding before the boards are stacked and packed. It plays a crucial role in defining the final dimensions, edge quality, and appearance of the finished product.

Functionality and Technical Features

The primary task of the bundler is to trim the edges of the plasterboards, removing any irregularities or excess material created during the cutting processes. This ensures that every board has clean, straight, and accurately edges, meeting commercial and technical standards.

Key features of the bundler include:

- High-performance cutting saws, designed for durability and precision cutting

- Smooth and synchronized feeding system, which stabilizes the board during trimming for consistent edge quality

- Heavy-duty frame and linear guides, minimizing vibration and ensuring long-term accuracy

- Automation control, enabling recipe-based trimming settings and adjustments

Edge Taping Capability

For added functionality, the bundler can be equipped with an Edge Taping Unit, which applies protective tape to the cut board edges.

This is especially useful for:

- Reducing edge chipping during handling and transport

- Enhancing aesthetic appearance of finished boards

- Meeting specific market or project requirements

Importance in the Production Line

The bundler is more than a trimming unit—it is a critical finishing system that directly impacts:

- Dimensional accuracy of each board

- Edge smoothness and structural integrity

- Overall product presentation and handling safety

- Stacking precision in the packaging process

A well-designed bundler with high-quality saws and controlled feeding not only boosts production reliability but also reduces rework, material waste, and mechanical wear in downstream equipment.

In short, the bundler ensures that each board leaves the line with clean edges and a professional finish, ready for market delivery or on-site use—completing the production process with precision and quality.