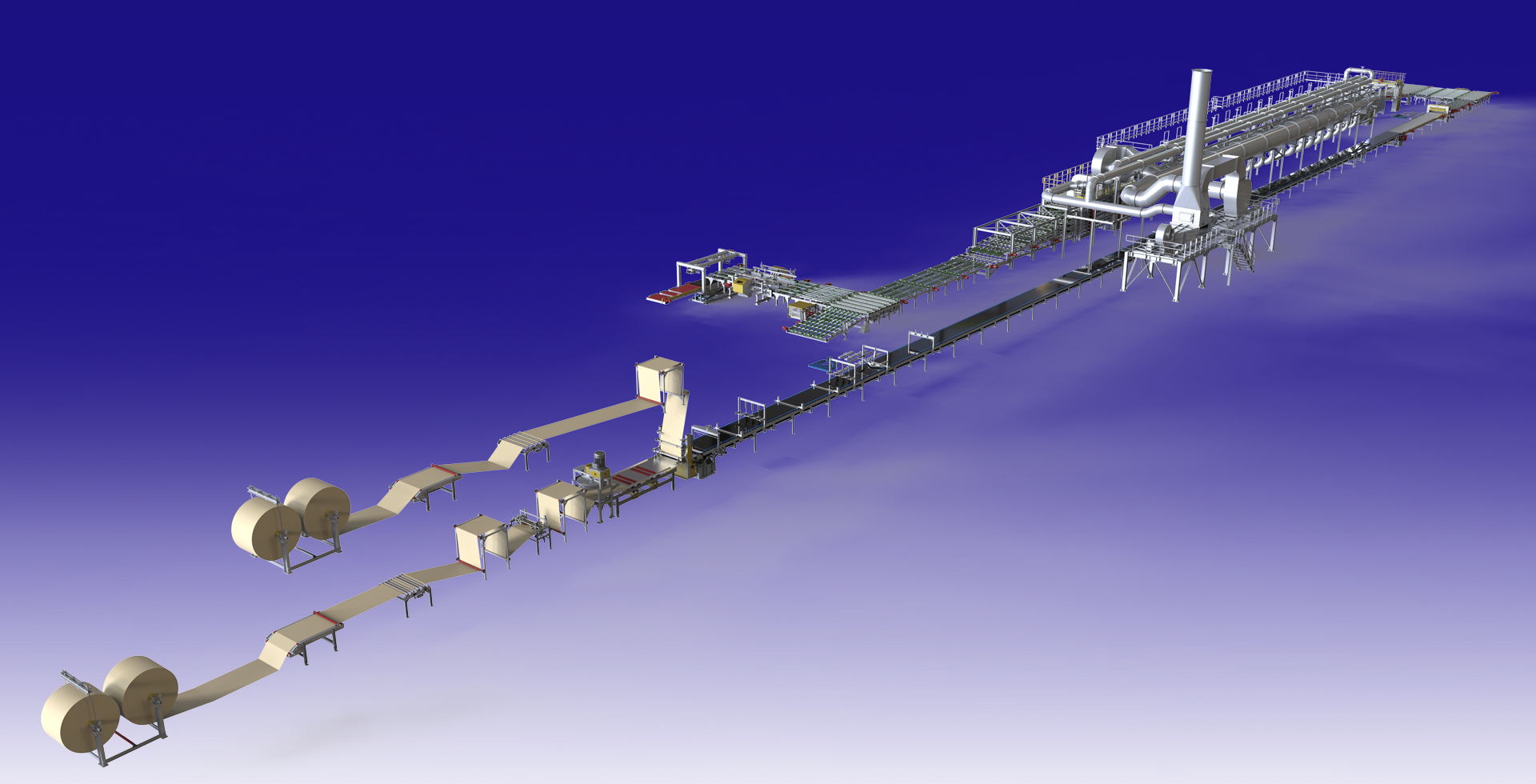

Cross-Conveying Units

– Smooth Transfer for Seamless Flow

The Cross-Conveying System is a crucial link in the plasterboard production line, responsible for directing finished boards from the cutting section either toward the dryer for curing or to the bundling and stacking section for packaging and storage. This system ensures that boards are moved safely, smoothly, and without damage during transfer operations.

The unit is composed of several key elements working in coordination:

- Cross-conveyor - moves boards laterally from the main line.

- Board turner - rotates boards as needed for correct orientation in downstream processes.

- Collecting conveyor - aligns and gathers boards before further transfer.

- Reject conveyor

To ensure durability and optimal performance, the conveying system uses high-quality belts engineered for low friction, minimal elongation, and resistance to wear—helping to maintain consistent board alignment and reduce maintenance downtime.