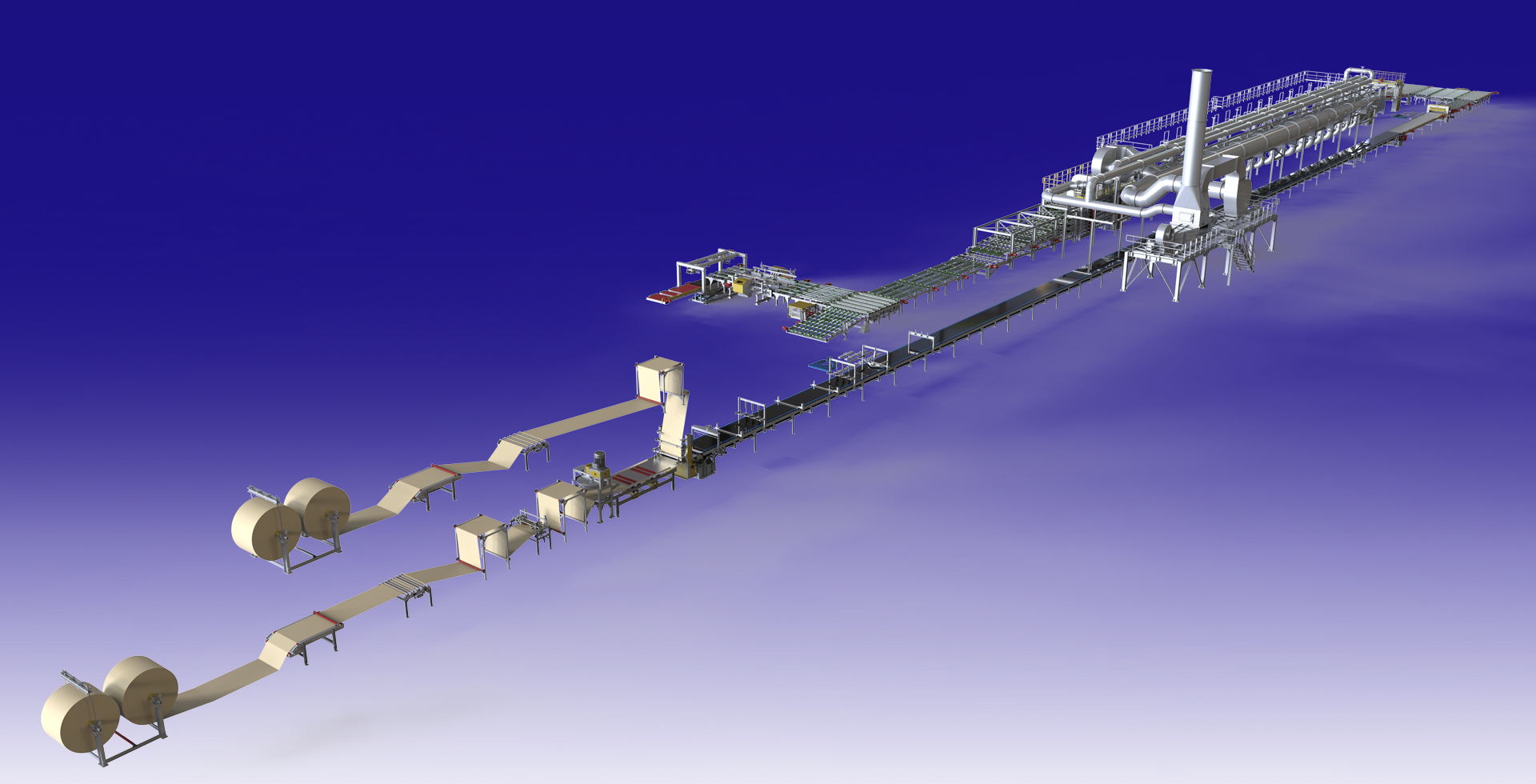

Wet materials preparing station

The Wet Materials Preparation Station is a core component of the plasterboard production line, designed to ensure the continuous and highly accurate supply of all liquid materials required by the production process. These materials include process water, foam, retarder, silicone, plasticizer, and other wet additives, all of which must be dosed precisely according to the production recipe to maintain the quality and consistency of the final product.

Process Water System

Process water is the primary liquid component in gypsum board manufacturing. Its correct dosage directly influences the flowability, setting time, and strength of the gypsum slurry. To meet these demands, the process water system is equipped with:

- Process water tank

- Dosing pump A high-accuracy dosing pump for precise flow control

- Transfer pump A transfer pump for steady material feediol

- Valves Automated valve systems to regulate flow and ensure seamless integration with the mixing process

This system ensures that water is delivered in exactly the right quantity, contributing to a stable and repeatable production process.

Wet Additive System

Wet additives such as foam, retarder, silicone, and plasticizer each play a specific role in enhancing board performance—whether by controlling setting time, improving water resistance, or enhancing flexibility. Each of these additives is handled through an independent, specialized system consisting of:

- Storage tanks for each liquid component

- Agitators to maintain homogeneity and prevent sedimentation

- High-precision dosing pumps for exact recipe-based delivery

- Transfer pumps and automated valves for efficient and controlled feeding into the mixing unit

Foam Generation – A Key to Board Quality

Among the wet additives, foam holds special importance. While it may appear simple—made from air, soap, and water—the reality is that foam quality, consistency, and density have a direct impact on board structure, weight, and surface finish. Our foam generation system, developed through years of experience and technical expertise, is designed to deliver superior performance. It is equipped with world-leading components, including:

- High-efficiency foam generators

- Precision dosing and transfer pumps

- Reliable valve systems

This ensures the foam produced consistently meets strict quality parameters, contributing to lightweight yet durable boards with optimal internal structure.