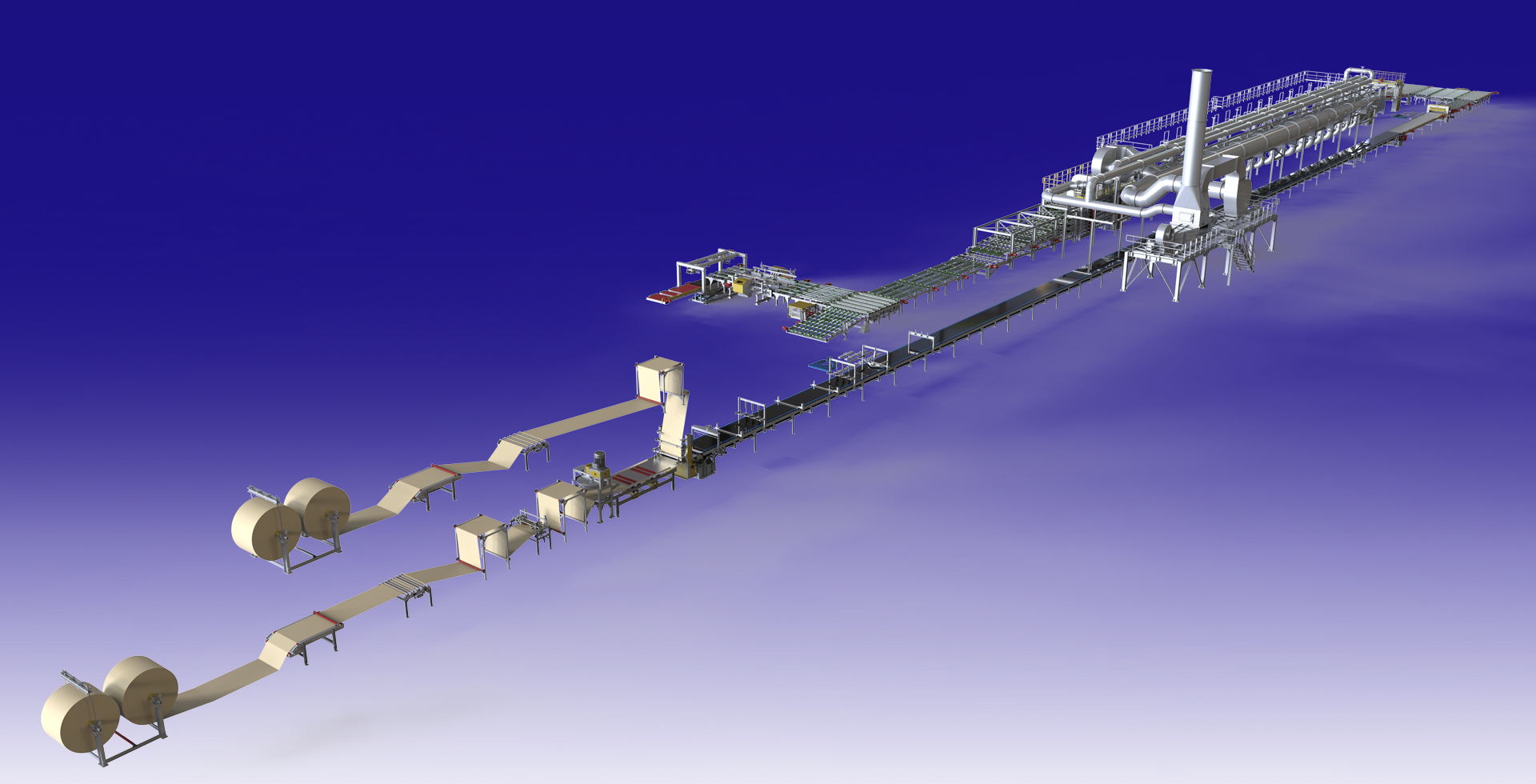

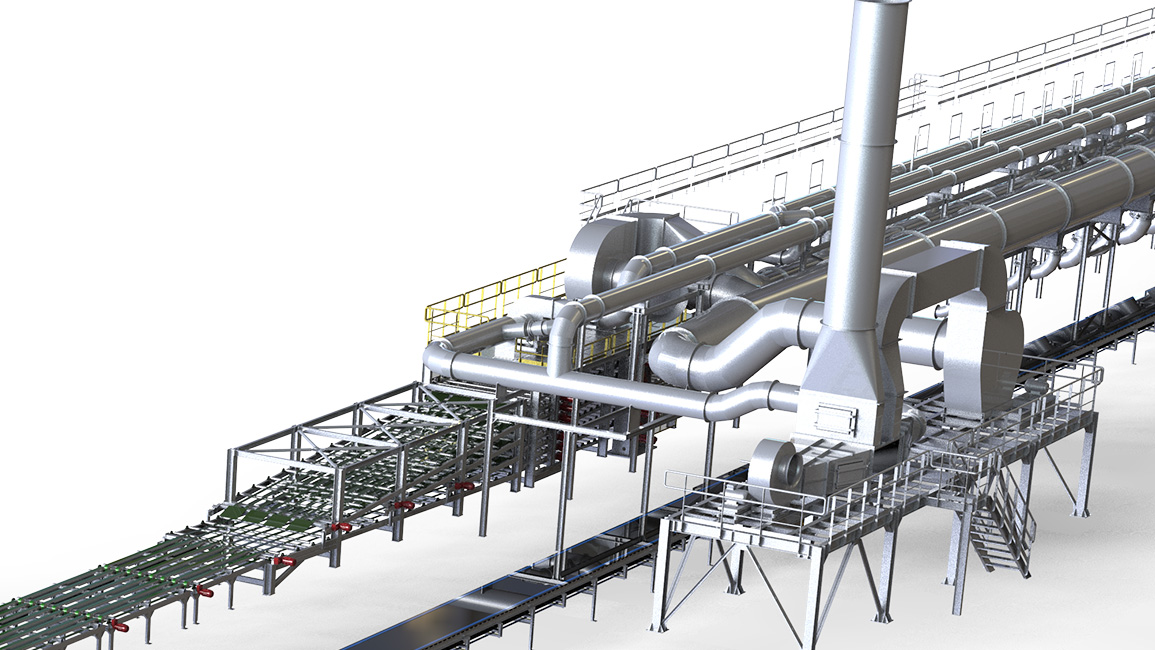

Heat Recovery System

– Smart Energy Efficiency for Dryer Operation

The Heat Recovery System is a vital component in the plasterboard production line used to reduce energy consumption by recovering a portion of the heat from the dryer’s exhaust air. This recovered heat is then used to preheat the combustion air and fresh air supplied to the dryer.

By utilizing otherwise wasted thermal energy, the system significantly improves the overall energy efficiency of the drying process. The performance, design, capacity, and efficiency of the heat exchanger directly influence how much heat can be recovered and reused, impacting both fuel consumption and operating costs.

Engineered for reliability and thermal performance, the heat recovery system supports sustainable production, reduces emissions, and contributes to the cost-effective operation of the plasterboard line.