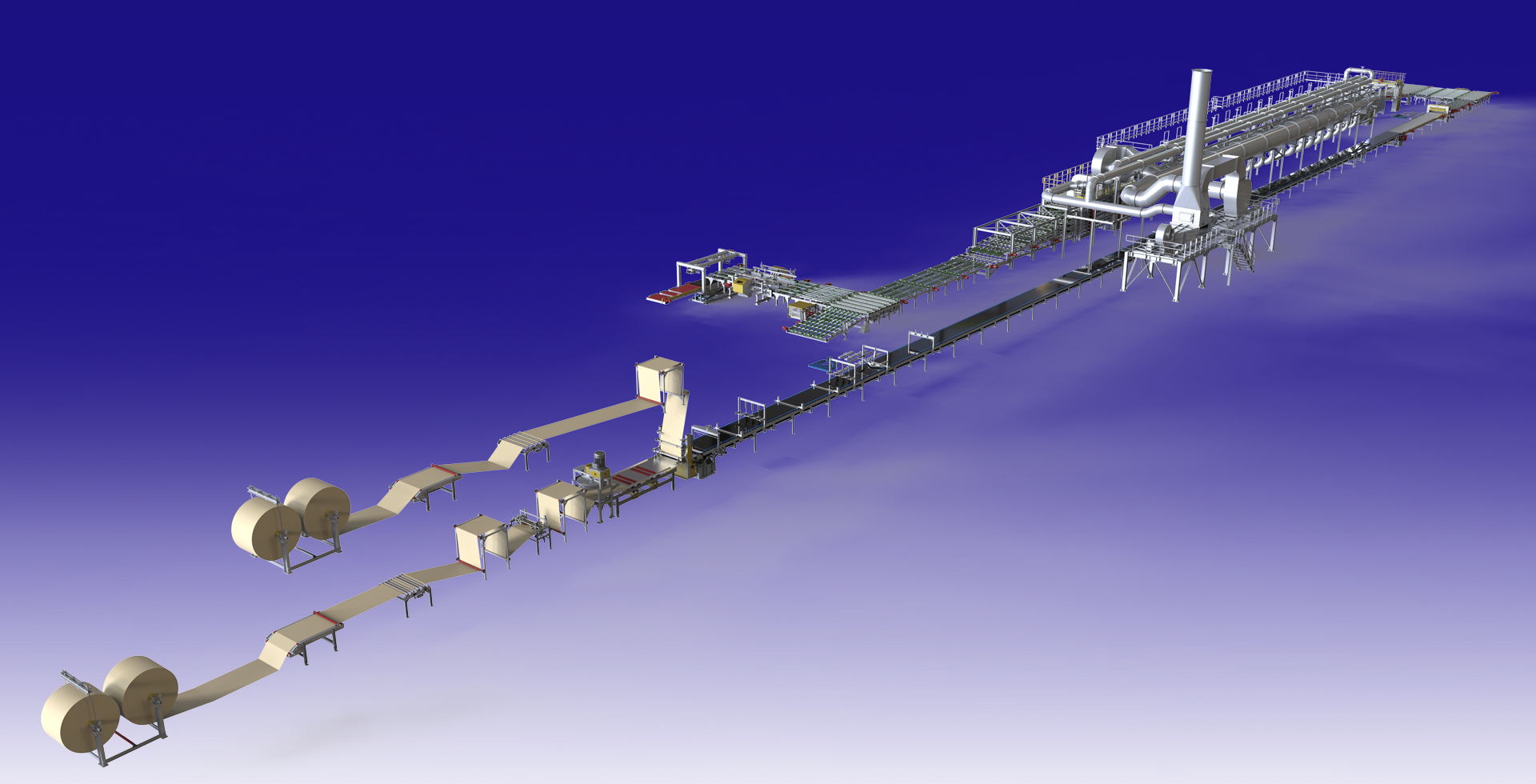

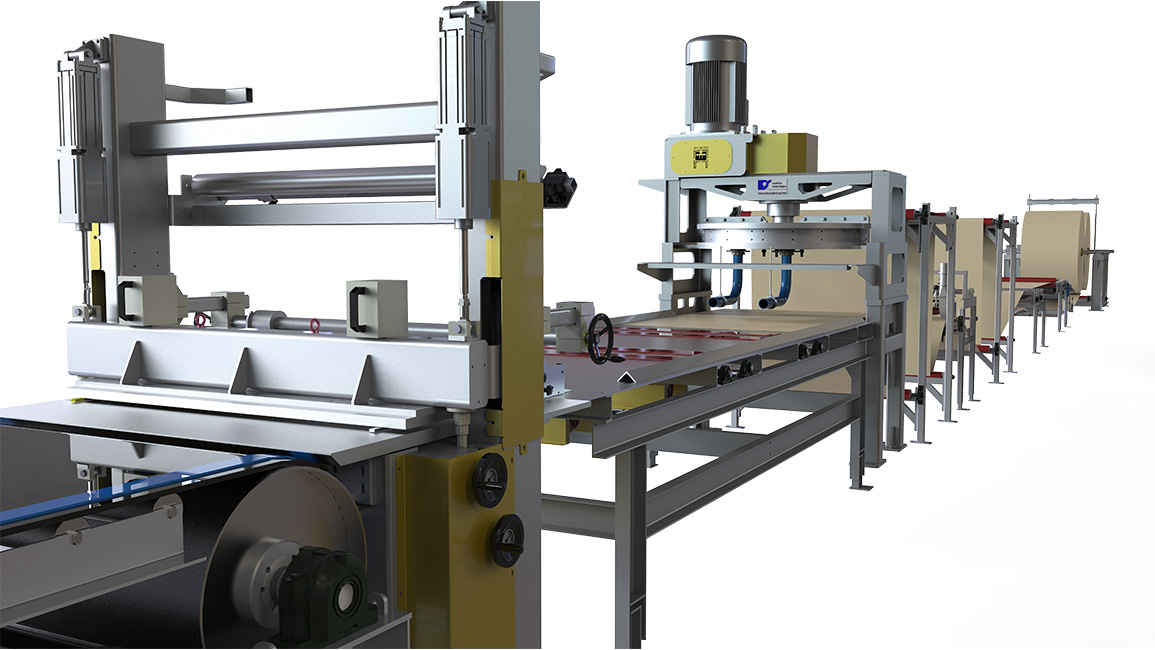

Stucco mixer

What Is the Mixer in a Plasterboard Production Line?

The plasterboard mixer, often called a continuous mixer, is designed to combine gypsum plaster, process water, foam, and chemical additives into a homogeneous slurry. This slurry is then poured onto the moving lower cardboard to begin forming the board structure.

It is typically a horizontal, high-shear, continuous mixing unit, engineered to deliver consistent and thorough mixing at high speeds with minimal variation. The quality and stability of this mixture directly affect every plasterboard coming off the line.

Why the Mixer Is Critically Important?

1. For Plasterboard Quality

- Slurry homogeneity: The mixer must create a perfectly uniform slurry so that every square centimeter of the board has the same structure, density, and strength.

- Additive activation: Proper dispersion of additives like foam, starch, retarder, and silicone only happens with effective mixing. Poor mixing can cause issues like uneven setting times, weak cores, surface defects, or poor fire resistance.

- Foam integration: Foam must be evenly distributed to control board weight and internal porosity. The mixer ensures this without collapsing the foam structure.

2. For the Production Line

- Continuous flow: The mixer feeds the forming section in real-time. Any disruption here can stop the entire line.

- Recipe flexibility: Modern mixers allow for fast recipe changeovers and adjustment, crucial for producing different board types (standard, fire-rated, moisture-resistant, etc.).

- Efficiency & control: A well-designed mixer helps reduce raw material waste, optimize set times, and prevent issues downstream like deformations or board breakage.

Advantages of a High-Quality Mixer

- Consistent output: Stable mixing ensures consistent board thickness, density, and mechanical properties.

- Precision dosing integration: The mixer can be tightly integrated with dosing systems to react in real time to material flow rates and changes.

- Reduced maintenance: Advanced designs reduce clogging and wear, minimizing downtime.

- Easy cleaning and access: Essential for smooth changeovers and hygiene, especially when switching between board types.

Potential Drawbacks or Challenges

- High sensitivity to input accuracy: The mixer depends on perfectly metered input. Errors in dosing (especially foam or water) can quickly affect product quality.

- Maintenance demand: The shear forces and continuous flow require robust components and regular maintenance (especially on mixing blades and shaft seals).

- Start-up and shut-down precision: Slurry hardens quickly, so delays during line startup or shutdown can lead to material buildup or equipment blockages.

Conclusion: The Mixer as the Heart of the Line

The mixer is not just a processing machine—it’s the core of product quality and line stability. A well-designed, properly maintained mixer ensures:

- Homogeneous and high-quality gypsum slurry

- Reliable integration of water and additives

- Stable production flow without interruptions

- Flexibility to meet diverse production requirements

In essence, when the mixer runs smoothly and accurately, the entire plasterboard line performs efficiently, and the quality of the end product meets both technical standards and customer expectations/