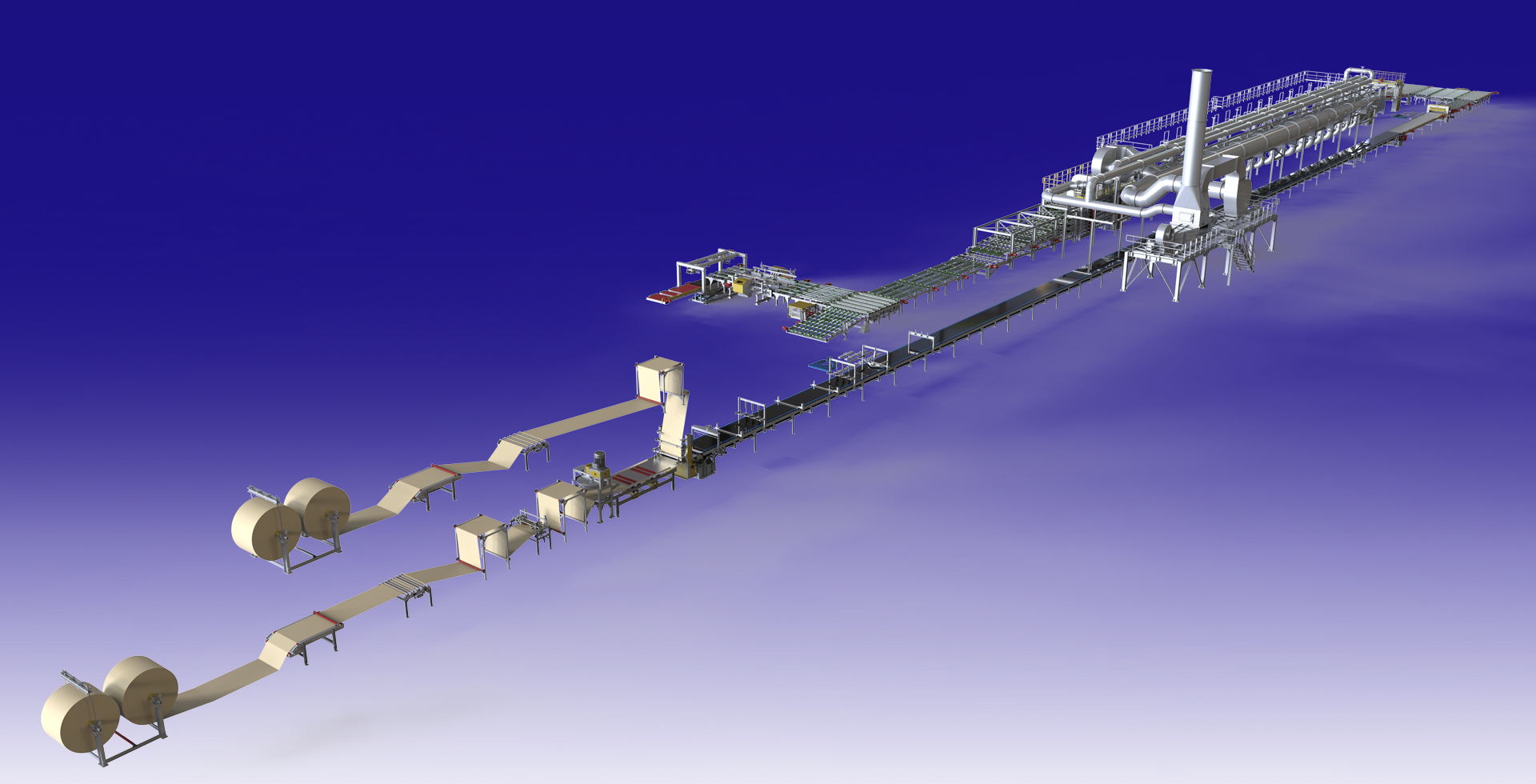

Cardboard preparing and handling unit

The Cardboard Preparing and Handling Unit is one of the several units of the plasterboard production line. Its main job is to feed the cardboard—used as the top and bottom surfaces of the board—into the system in a smooth and controlled way. This unit takes care of tasks like unwinding the cardboard rolls, keeping the tension right, aligning the sheets properly, and applying any necessary treatments before the cardboard reaches the forming section. A stable and well-prepared cardboard feed is critical for proper bonding with the gypsum core and helps ensure the final boards are strong and have a clean, smooth finish. By maintaining consistent feed rates and accurate positioning, this unit helps optimize production flow and minimize material waste.

The Cardboard Preparing and Handling Unit includes several key pieces of equipment, each responsible for a specific step in the process. These are:

- Cardboard reels, which hold the raw cardboard rolls used in production

- Cutting and jointing table, where the ends of the cardboard rolls are cut and joined for continuous feeding

- Cardboard pulling machine that feeds the cardboard forward at a controlled speed

- Cardboard cutting machine used for cutting the cardboard to the required width

- Cardboard tensioning machine, which maintains proper tension to prevent wrinkles or slack

- Cardboard aligning machine that ensures the cardboard stays centered and properly positioned

- Cardboard edge preparation (creasing) machine that processes the edges for easy and accurate folding